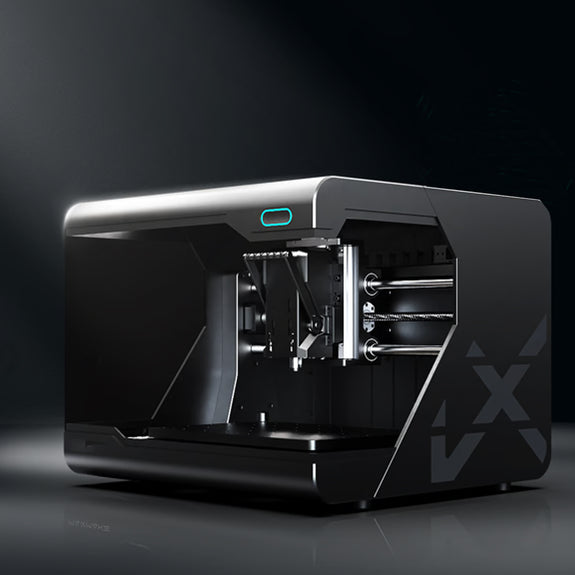

RapidCNC

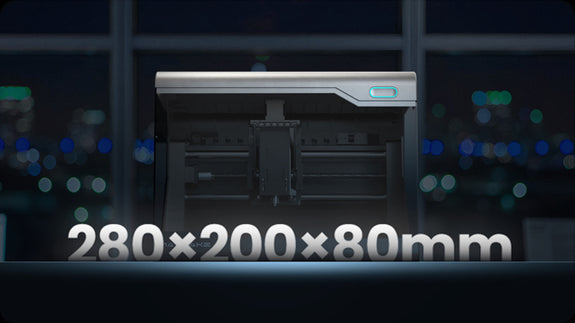

Quick Tool Changer | 3D Probe | 280*200*80mm Working Area | 0.02mm High Precision | Snap-on Laser Module | Use Right out of Box

Precision, power, and simplicity combined! This model achieves 0.02mm high precision while featuring a Quick Tool Change system, maintaining plug-and-play simplicity to make professional-grade machining accessible to makers, hobbyists, and engineers alike.

Simply unbox, connect the power, and start your first project within minutes — no technical expertise or assembly required.

Featuring the industry's most compact quick-change spindle for tool swaps in seconds, combined with an automatic tool setter that ensures perfect alignment every time

![]()

With its snap-on quick-attach design, the 10W blue laser module installs instantly without spindle removal, allowing seamless switching between cutting and engraving

A specialized XYZ multi-axis triggering system achieves 0.01mm precision (10× improvement) through gold-plated tungsten components, providing ultra-stable feedback for 3D metrology and precision positioning

The 3D Touch Probe ensures high-precision measurement with intelligent dynamic position calibration, delivering <±0.02 mm unidirectional repeatability for consistent and stable results

The system combines real-time toolpath visualization with 3D probe scanning to instantly generate height maps for precision machining

The 250W brushless spindle delivers professional cutting performance at speeds up to 1000mm/min, handling everything from delicate engravings to robust material removal.

With a generous 280×200×80mm working area, which accommodates larger projects while maintaining precise dimensional accuracy.

The system supports mainstream CAM software such as Fusion 360, VCarve, FreeCAD, and Carveco. It is compatible with popular control software like UGS and Candle, and works with a variety of industrial-grade CAM post-processors—enabling a seamless workflow from design to machining and meeting the needs of multiple application scenarios

Constructed from high-strength cast aluminum and engineered with a topology-optimized structure, this rigid frame offers up to 150% greater stiffness compared to conventional CNC frames of the same weight. Advanced mechanical simulations effectively suppress machining vibrations, allowing for a compact design without sacrificing heavy-duty performance